The art of metamorphosis

Back to productsThe process behind our core business explained.

Got an inquiry?

Contact us

1/ Polymerisation

from CPL to Nylon 6 polymers

A nylon 6 granule starts life as caprolactam (CPL), an organic compound that has 6 carbon atoms, hence the name. When caprolactam is heated to a set temperature in a nitrogen atmosphere, the reaction of step-growth polycondensation occurs,

synthesizing a string of nylon 6 polymers. The trademark granules or chips are born when the PA6 string is cooled and then cut to size in a granulator, after which the pellets are drained, dried and stored. The caprolactam residue is extracted from the excess water and recycled back into the reactor, so nothing goes to waste.

2/ Stretching the point

from tiny granules to textured yarns

First, the PA6 granules are smelted in an extruder. The molten polymer is then pumped into a spinning machine, which siphons precise volumes of the product through a filter system and a perforated spinneret. In a later stage of the extrusion process, the partially orientated filaments are air-quenched and pre-tensioned in a specially designed chute and converge into oiled yarns before being "drawn" (stretched) and spun to achieve the desired tensile strength, size and orientation. The morphology of the fibers will have a great effect on their ability to absorb dye at a later stage.

After the spin-drawing, the yarn is primed for texturing. The thread is run through a special chamber filled with hot air. By creating an overfeed,the yarn is naturally crimped and goffered as it heats up on the go.. It is then sent to a cooling drum, which fixes in place the uniform texture and the structural features of the yarn—breathability, bulk, warmth, softness, opaqueness, stretch and shrink factor, and so on. Finally, the yarn is relaxed, entangled and automatically collected on cylindrical bobbins, which are replaced when fully wound.

3/ Forging the bond

from textured yarns to heat-set yarns

Twisting and Heat-setting: from textured yarn to finished product

In the last station of our integrated production line, the bobbins are placed in a twisting machine, which uses the centrifugal force of rotation to ply together the individual strands as they are fed through the system.

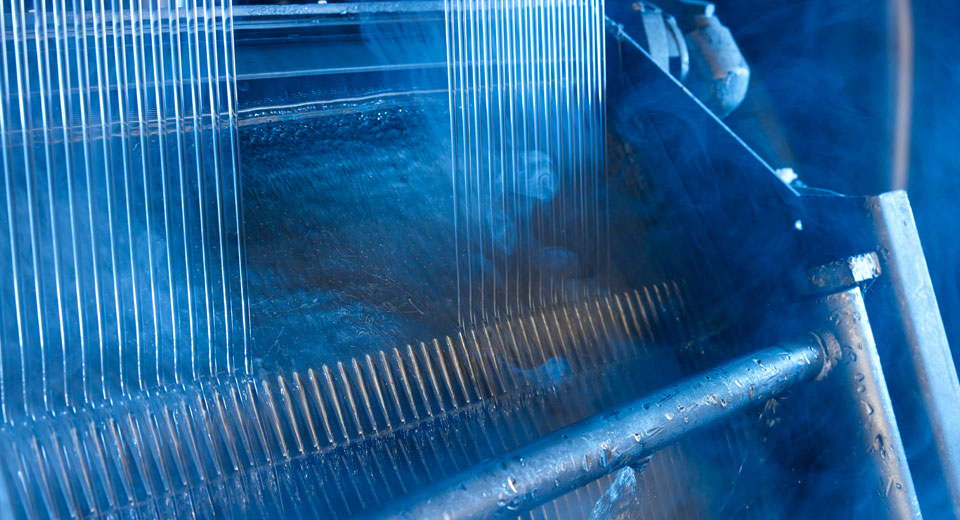

This twist enhances the dimensional stability and strength of the yarn, and gives it more substance. Heat-setting or thermal fixation, finally, is the process in which the twisted yarn is exposed to a carefully calibrated mixture of heat and humidity, which determines its torque and toughness, thereby improving the overall quality and performance of the finished product.

© 2024 - NYOBE NV